Selected references

Construction of cement plant 3 300 t/d

Material preparation 1 200 – 1 400 t/h

Main equipment of the crushing plant: 2 200 x 12 150 mm apron feeder, 1 000 mm roller screen, ODN 1214 impact crusher, transport and de-dusting equipment

Main equipment of the pre-homogenizing storage: ZH 34-V 4.450 stacker, SPMV 34/32.5 scraper, transport equipment

Input material: calcareous clay fraction 0 – 500 mm, 1.4 t/m3, up to 10%

Output product: fraction 0 – 70 mm, 10% up to 90 mm

Raw meal production 300 t/h

Main equipment: LM 48.4 vertical mill, high-efficiency cyclones Ø 4.5 m, transport and de-dusting equipment

Input material: limestone, clay, sand, iron correction fraction 0 - 70 mm, 10% up to 110 mm

Output product: fineness 12% R0.09 mm

Kiln line 3 300 t/d

Main equipment: LUCY 5ST 2/650.800 preheater, KS calciner, rotary kiln Ø 4.6 x 68 m, grate cooler 76.1 m2

Clinker storage

Main equipment: KTS 800 chain conveyor, silo Ø 28 x 43.5 m, de-dusting equipment

Cement production 220 t/h

Main equipment: vertical mill LM 56.3-3C/S, Jet fabric filter for product separation 695 000 m3/h, combustion chamber 9 100 kW

Input material: clinker, gypsum, slag

Output product: 3 300 ± 3% cm3/g (Blaine), < 0.3% H2O

Reconstruction of cement plant 1 200 t/d

New primary crushing plant 370 t/h and pre-homogenizing storage with 20 000 t capacity

Main equipment: OKD 2000x2000 impact-hammer crusher, belt conveyor, KTM 360 vertical mill, circular pre-homogenizing storage, stacker, scraper

Outlet product: fineness 5% R25mm

Reconstruction of raw mill 2 x 48 t/h and homogenizing silo with 6 000 t capacity

Main equipment: 2 original mills Ø 3.1 x 6 m, new LTRR 2000 separators, exhaust fans, de-dusting, screw conveyor, bucket elevator, silo Ø 14 m x 60 m

New kiln line 1 200 t/d

Main equipment: LUCE five-stage cyclone preheater, rotary kiln Ø 3.4 x 46 m on three supports, RCH30/0747 grate cooler, de-dusting

Fuel: natural gas or coal, in combination if needed

Heat consumption: 3 070 kJ/kg of clinker

New coal grinding plant 10 t/h

Main equipment: vertical coal mill, air separator, transport

Output product: fineness 12% R0.09 mm, moisture 1%

Kiln line 3 500 t/d

Main equipment: LUCY 5ST 2/650.800 preheater, KKN - AS calciner, rotary kiln ø 4.4 x 64 m, cooler 80.3 m2

Modernization of kiln line 1 900 t/d

Main equipment: original rotary kiln, new SCC calciner, new KIDS cooler

AF ratio (substitution of noble fuels for secondary fuels) 80%

NOx < 500 mg/Nm3, CO = 500 mg/Nm3

Heat consumption 3 447 kJ/kg of clinker

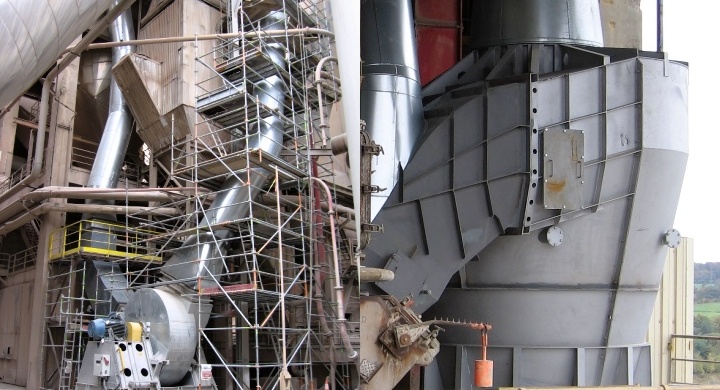

Installation of preheater chloride bypass

Main equipment: cooling chamber, piping, fans, flaps, compensators, cyclones, structures, platforms, heat insulation

Extension of calcining channel

Original state: Calcining channel in five-stage preheater for mazut burning. When burning solid fuels, a portion of the energy attained could not be used, deposits formed and equipment became clogged.

State after modification:

- Increased duration that combustion products remained in the calciner by 4 seconds, to a total of 6.2 seconds.

- By increasing the height of the calciner by 29.6 m, the path for combustion products was doubled in length, by more than 60 m.

- The combustion process was improved and the thermal efficiency of the entire system was increased.

- Product quality was improved, which was brought about by more uniform and stable clinker burning.

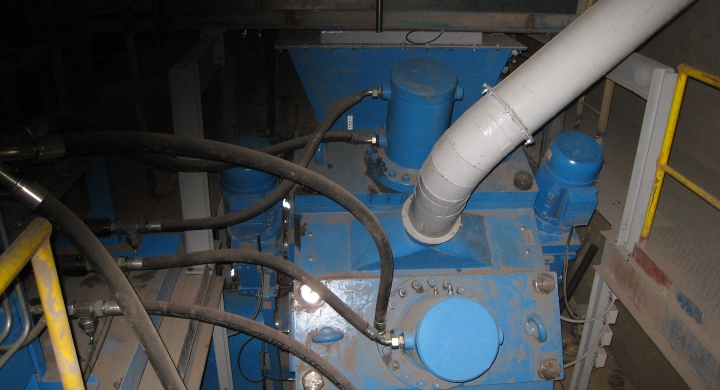

Raw meal pregrinding plant

Main equipment: PREMILL PM 1400 horizontal mill

Capacity: 205 t/h

Input material: raw meal fraction 0 - 45 mm, moisture < 3.0%

Output product: fineness max. 10% R 5 mm

Raw meal pregrinding plant - VIDEO

Raw meal grinding plant 250 t/h

Main equipment: ball mill on sliding bearings Ø 5.2 x 13.5 m

Output product: fineness 0 - 25 mm

Cement grinding plant

Main equipment: ball mill Ø 4.0 x 13.75 m

Input material: clinker and gravel

Capacity - product of CEM I/42.5 R: 85 t/h

Capacity - product of CEM II/B 32.5 R: 95 t/h

Output product: fineness 10% R40 and 3500 Blaine

Modernization of cement grinding plant

Main equipment: new two-chamber tube mill Ø 4.2 x 14.5 m, separation circuit fitted with VTP 2900

Capacity - product of CEM I/42.5R: 79 t/h

Capacity - product of CEM II/B-S32.5 R: 97 t/h

Cement grinding plant revamping with transfer into closed circuit

Main equipment: VTP 2700 dynamic separator

Input material: clinker, gypsum, additives

Output product 1: capacity 100 t/h, fineness 3000 cm2/g

Output product 2: capacity 60 t/h, fineness 4500 cm2/g